Resin Lens Edging: A Comprehensive Guide

In the intricate world of optics, the process of edging resin lenses stands as a critical step in crafting high-quality eyewear. This comprehensive guide delves into the nuances of resin lens edging, providing a detailed overview of the techniques, technologies, and considerations involved. Whether you’re an optician, a lens manufacturer, or simply curious about the process, this article will equip you with the knowledge to understand and appreciate the precision required in this essential aspect of lens production.

The term “resin lens edging” refers to the process of shaping and finishing the edges of lenses made from resin materials, typically used in eyeglasses. This involves cutting, grinding, and polishing the lens to fit the frame accurately and meet the wearer’s visual requirements. Unlike glass lenses, resin lenses, also known as plastic lenses, present unique challenges and opportunities in the edging process. Their inherent properties, such as flexibility and susceptibility to heat, necessitate specialized equipment and techniques to ensure optimal results.

The importance of proper resin lens edging cannot be overstated. A poorly edged lens can lead to a variety of issues, including:

- Poor fit within the frame, causing instability and discomfort.

- Optical distortions, affecting the wearer’s vision.

- Increased stress on the lens, potentially leading to breakage.

- Aesthetically unpleasing results, impacting the overall appearance of the eyewear.

Therefore, mastering the art of resin lens edging is crucial for producing high-quality eyewear that meets the needs of both the wearer and the optical professional.

Understanding Resin Lens Materials

Before delving into the specifics of edging, it’s essential to understand the materials commonly used for resin lenses. The most prevalent materials include:

- CR-39: A thermoset plastic offering a good balance of optical clarity, impact resistance, and affordability. It’s a widely used material for standard prescription lenses.

- Polycarbonate: Known for its exceptional impact resistance, making it a popular choice for safety eyewear and children’s glasses. Polycarbonate lenses are thinner and lighter than CR-39 but can be more challenging to edge.

- Trivex: Another impact-resistant material, Trivex provides excellent optical clarity and is lightweight. It’s often preferred for its superior optical properties and durability.

- High-Index Plastics: These materials offer a higher refractive index, allowing for thinner and lighter lenses, particularly beneficial for individuals with strong prescriptions. They can be more delicate and require precise edging techniques.

Each material has unique properties that influence the edging process. For example, polycarbonate and Trivex are more flexible and require careful handling to prevent chipping or cracking. High-index lenses are often more brittle and demand precise cutting and polishing to avoid imperfections.

The Resin Lens Edging Process: A Step-by-Step Guide

The resin lens edging process typically involves several key steps, each contributing to the final shape and finish of the lens.

Lens Blank Preparation

The process begins with a lens blank, a pre-formed lens that requires edging. The lens blank is selected based on the patient’s prescription and the frame specifications. Before edging, the lens blank undergoes several preparation steps, including:

- Verification of Prescription: Ensuring the correct lens power and other parameters are accurately recorded.

- Blocking: Attaching the lens to a blocking device, which secures the lens during the edging process. This is crucial for maintaining the lens’s position and preventing slippage.

- Trace Frame (or Use Existing Pattern): The frame is scanned or measured to determine the exact shape and dimensions of the lens required. This information is used to program the edging machine.

Edging Machine Programming

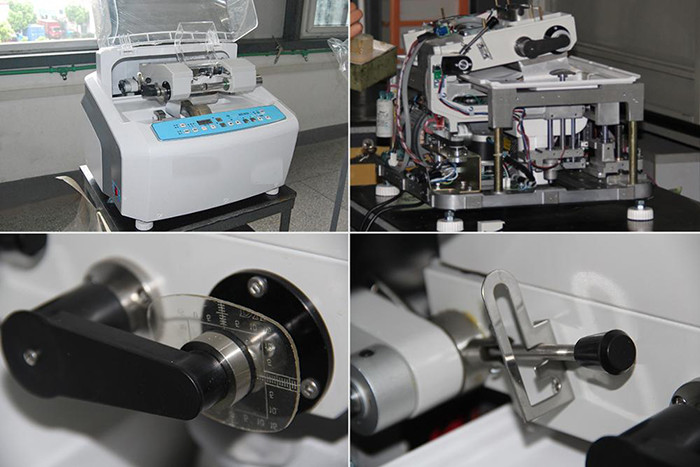

Modern resin lens edging machines are highly automated and require precise programming. The optician or technician enters the frame shape, lens material, and other relevant parameters into the machine. The machine then calculates the optimal cutting path and grinding parameters to achieve the desired lens shape.

Cutting and Grinding

The lens is then placed in the edging machine, which uses diamond-coated wheels or other cutting tools to remove excess material and shape the lens. The machine typically performs several grinding passes, each with a progressively finer grit, to achieve the desired edge shape and smoothness. The machine may also incorporate beveling, grooving, or drilling features, depending on the frame type and design. This is where the bulk of the work for resin lens edging is done.

Polishing

After grinding, the lens edges undergo a polishing process to remove any remaining imperfections and create a smooth, transparent finish. This step is crucial for both optical clarity and aesthetics. Polishing can be performed using various methods, including felt wheels with polishing compounds or specialized polishing machines. The quality of the polishing significantly impacts the final appearance and performance of the lens.

Inspection and Quality Control

Throughout the resin lens edging process, rigorous inspection and quality control measures are employed. The lens is examined for:

- Accuracy of Shape and Size: Ensuring the lens fits the frame perfectly.

- Edge Quality: Checking for any chips, cracks, or imperfections.

- Optical Clarity: Verifying the absence of distortions or blemishes.

Any lenses that fail to meet the required standards are either reworked or discarded. The goal is to produce a lens that meets the highest standards of optical quality and visual comfort.

Advanced Techniques and Technologies in Resin Lens Edging

The field of resin lens edging is constantly evolving, with advancements in technology leading to greater precision, efficiency, and customization. Some notable developments include:

- Automated Edging Machines: These machines offer enhanced precision, speed, and ease of use. They can handle a wide range of lens materials and frame styles.

- Digital Lens Scanning: Digital scanners accurately capture the frame shape and dimensions, eliminating the need for manual tracing and minimizing errors.

- Specialized Cutting Tools: Diamond-coated wheels and other cutting tools are designed to optimize the cutting process for different lens materials, reducing chipping and improving edge quality.

- Beveling and Grooving Capabilities: Advanced edging machines can create various bevels and grooves to accommodate different frame styles, such as rimless frames and grooved frames.

- Drilling and Customization: Some machines offer the ability to drill holes in the lenses for specialized frame designs, such as drill-mount frames.

Challenges and Considerations in Resin Lens Edging

While resin lens edging has become highly sophisticated, several challenges and considerations remain:

- Material Sensitivity: Each lens material has unique properties that require specific edging parameters. For example, polycarbonate lenses are more prone to chipping, requiring slower cutting speeds and specialized tools.

- Frame Variations: Different frame styles, shapes, and materials demand customized edging techniques. The optician or technician must adapt the process to ensure a perfect fit.

- Prescription Complexity: High-index lenses and complex prescriptions can pose challenges, requiring more precise edging and careful handling.

- Equipment Maintenance: Regular maintenance and calibration of edging machines are essential for optimal performance and accuracy.

- Training and Expertise: Skilled opticians and technicians are crucial for producing high-quality lenses. Proper training and expertise are essential for mastering the art of resin lens edging.

The Future of Resin Lens Edging

The future of resin lens edging is likely to be shaped by ongoing technological advancements. We can anticipate:

- Increased Automation: Further automation of the edging process, leading to greater efficiency and reduced labor costs.

- Advanced Materials: The development of new lens materials with improved optical properties and durability.

- Personalized Lens Design: Customized lens designs tailored to the individual wearer’s visual needs and lifestyle.

- Integration with Digital Technologies: Seamless integration of edging machines with digital lens design software and other technologies.

These innovations will continue to elevate the quality and performance of eyewear, enhancing the visual experience for wearers worldwide.

Conclusion: Precision and Perfection in Resin Lens Edging

Resin lens edging is a critical process in the production of high-quality eyewear, demanding precision, skill, and advanced technology. From the careful selection of lens materials to the meticulous shaping and polishing of the edges, every step in the process contributes to the final product’s optical quality, fit, and aesthetic appeal. As technology continues to advance, the future of resin lens edging promises even greater precision, efficiency, and customization, ensuring that individuals worldwide can enjoy the benefits of clear, comfortable, and stylish vision. Understanding the intricacies of resin lens edging is essential for anyone involved in the optical industry, from opticians to lens manufacturers, and ultimately, for the millions of people who rely on eyeglasses for their daily vision needs. The focus on delivering the best possible vision through precision resin lens edging is paramount.

[See also: Related Article Titles: Lens Materials: A Comprehensive Guide, Understanding Eyeglass Frames, The Importance of Accurate Prescription in Eyewear]