Optimize Your Engine: Master Distributor Point Adjustment for Peak Performance

The internal combustion engine, a marvel of engineering, relies on a precise dance of components to convert fuel into motion. Among these critical elements is the distributor, responsible for delivering the spark that ignites the fuel-air mixture within the cylinders. A key aspect of distributor functionality is the distributor point adjustment. This article delves into the intricacies of this vital process, explaining its significance, the procedures involved, and the benefits of mastering it to optimize your engine for peak performance.

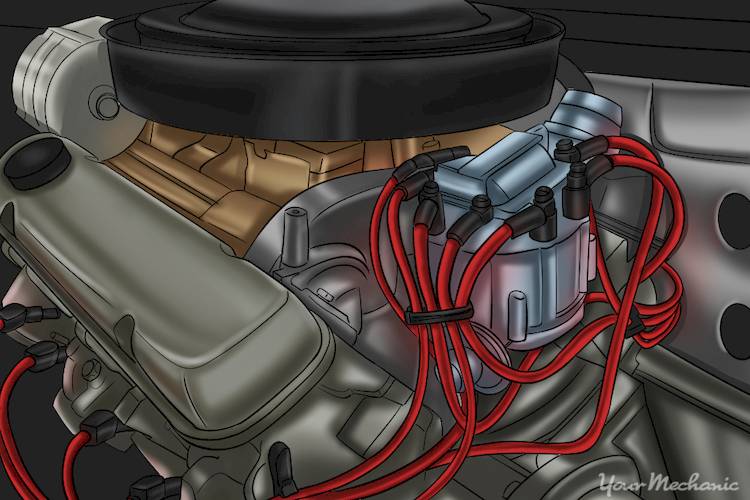

The distributor, a relic of older engine designs, plays a crucial role in the timing of the spark. In essence, it acts as a gatekeeper, directing high-voltage electricity from the ignition coil to the spark plugs at the precise moment each cylinder needs to fire. This timing is not arbitrary; it’s meticulously calculated to ensure optimal combustion and engine efficiency. The distributor points, also known as contact points, are the heart of this timing mechanism. They open and close, interrupting the primary circuit of the ignition coil, which in turn generates the high voltage needed for the spark plugs. Accurate distributor point adjustment is therefore paramount.

Understanding the Significance of Distributor Point Adjustment

Why is distributor point adjustment so crucial? The answer lies in its direct impact on several key aspects of engine performance:

- Ignition Timing: The precise moment the spark plug ignites the fuel-air mixture is dictated by the opening and closing of the points. Incorrect adjustment leads to improper ignition timing, either too early (advanced) or too late (retarded). This can result in reduced power, poor fuel economy, and even engine damage.

- Engine Efficiency: Optimal combustion translates to better fuel efficiency. When the spark occurs at the correct moment, the fuel burns completely, maximizing the energy released and minimizing wasted fuel.

- Engine Smoothness: Misfires and rough idling are often symptoms of incorrect distributor point adjustment. Proper adjustment ensures consistent and reliable sparking in each cylinder, leading to smoother engine operation.

- Component Longevity: Improper adjustment can put undue stress on the ignition coil and spark plugs, shortening their lifespan. A well-maintained distributor, including proper point adjustment, contributes to the overall longevity of engine components.

Tools and Materials Required

Before embarking on the distributor point adjustment, gather the necessary tools and materials. These typically include:

- Distributor Point Gauge: This specialized tool, often a small, flat piece of metal with a specific thickness, is used to measure the gap between the points.

- Screwdriver: A flathead screwdriver is essential for adjusting the points.

- Wrench: A wrench may be needed to loosen the distributor hold-down bolt.

- Feeler Gauges (Optional): Although a point gauge is preferred, a set of feeler gauges can be used in a pinch.

- Safety Glasses: Protect your eyes from debris.

- Work Light: Ensure adequate visibility.

- Owner’s Manual: Always consult your vehicle’s owner’s manual for specific instructions and specifications.

The Step-by-Step Guide to Distributor Point Adjustment

The process of distributor point adjustment involves several key steps. Always refer to your vehicle’s specific manual for precise instructions, as procedures may vary slightly between different makes and models.

- Safety First: Disconnect the negative (-) battery cable to prevent accidental sparking.

- Locate the Distributor: The distributor is typically located at the front or side of the engine, often near the carburetor or fuel injection system.

- Expose the Points: Remove the distributor cap by releasing the retaining clips or screws. Then, remove the rotor. This will reveal the points.

- Inspect the Points: Examine the points for wear, pitting, or burning. If they are severely damaged, they may need to be replaced before adjustment.

- Loosen the Adjustment Screw: Locate the adjustment screw on the points. This screw allows you to change the gap between the points.

- Rotate the Engine: Using a wrench on the crankshaft pulley bolt, rotate the engine until the points are fully open. The points are typically opened by a lobe on the distributor shaft.

- Insert the Point Gauge: Insert the correct thickness of the point gauge (as specified in your owner’s manual) between the points.

- Adjust the Gap: With the point gauge in place, adjust the points by turning the adjustment screw until the points just touch the gauge. You should feel a slight drag when pulling the gauge out.

- Tighten the Adjustment Screw: Once the gap is correctly set, tighten the adjustment screw.

- Double-Check the Gap: Re-insert the point gauge to ensure the gap remains correct after tightening.

- Reassemble the Distributor: Replace the rotor and distributor cap, ensuring the cap is properly seated and secured.

- Reconnect the Battery: Reconnect the negative (-) battery cable.

- Start the Engine and Check Timing (Optional): Start the engine and observe its performance. If you have a timing light, you can use it to verify the ignition timing, which should be within the manufacturer’s specifications.

Troubleshooting Common Issues

Even with careful execution, issues can arise during distributor point adjustment. Here are some common problems and their solutions:

- Engine Won’t Start: If the engine fails to start after adjustment, double-check the battery connection, the distributor cap for proper seating, and the point gap. Ensure the points are not closed.

- Rough Idling: Rough idling often indicates an incorrect point gap or ignition timing. Recheck the point gap and, if necessary, adjust the timing.

- Misfires: Misfires can be caused by incorrect adjustment, worn points, or faulty spark plugs. Inspect the spark plugs and points for damage.

- Backfiring: Backfiring can be a sign of advanced ignition timing. Check the timing and, if necessary, retard it slightly.

Beyond Adjustment: Distributor Maintenance

Regular distributor point adjustment is only one aspect of maintaining a healthy distributor. Other maintenance tasks include:

- Lubrication: Lubricate the distributor shaft and advance mechanism as recommended by the manufacturer.

- Inspection: Regularly inspect the distributor cap, rotor, and points for wear or damage.

- Replacement: Replace worn points, condensers, and other components as needed.

The Modern Relevance of Distributor Point Adjustment

While electronic ignition systems have largely replaced points in modern vehicles, a significant number of older cars and trucks still rely on this technology. Understanding distributor point adjustment remains relevant for owners of these classic vehicles, ensuring their continued operation and preservation. Furthermore, the principles of ignition timing and engine performance learned through working with points systems provide a valuable foundation for understanding more advanced engine technologies.

Even though modern vehicles use electronic ignition systems, the underlying principles of ignition timing and its importance to engine performance are still the same. The knowledge gained from understanding distributor point adjustment can be applied to understanding these more advanced systems.

Conclusion: Mastering the Art of Distributor Point Adjustment

Distributor point adjustment is a fundamental skill for anyone working on older internal combustion engines. By understanding the process, the tools required, and the potential issues, you can ensure your engine runs smoothly, efficiently, and reliably. This seemingly simple task holds the key to unlocking optimal engine performance and extending the life of your classic vehicle. The ability to correctly perform a distributor point adjustment is a testament to your mechanical aptitude and your dedication to keeping these classic machines running strong. Embrace the knowledge, hone your skills, and experience the satisfaction of a well-tuned engine.

[See also: How to Diagnose Engine Misfires, Understanding Ignition Systems, The Importance of Engine Timing]