Navigating the Maze: A Comprehensive Guide to 2 1/2 Dust Collection Fittings

The world of woodworking, metalworking, and even certain aspects of home improvement often generates a significant amount of airborne dust. This dust, if left unchecked, can pose serious health risks, damage equipment, and significantly impact the cleanliness of your workspace. Enter the unsung heroes of a clean and healthy workshop: dust collection systems. And a critical component of any effective dust collection system? 2 1/2 dust collection fittings.

This comprehensive guide will delve into the intricacies of these essential components. We’ll explore their various types, materials, applications, and considerations for selecting the right 2 1/2 dust collection fittings for your specific needs. Whether you’re a seasoned professional or a dedicated hobbyist, understanding these fittings is crucial for optimizing your dust collection system and maintaining a safe and productive work environment. This article is designed to be a thorough and insightful resource, providing you with the knowledge you need to make informed decisions about your dust collection setup.

Understanding the Role of Dust Collection Fittings

Before we dive into the specifics of 2 1/2 dust collection fittings, it’s important to understand their fundamental role within a dust collection system. These fittings act as the connectors, the conduits, the very lifeblood of your system, allowing for the efficient transfer of dust-laden air from the source (your tools) to the collection point (your dust collector). Without properly chosen and installed fittings, your system will suffer from leaks, reduced airflow, and ultimately, a less effective dust collection process.

The primary functions of 2 1/2 dust collection fittings include:

- Connecting Tools: Providing a secure connection between your power tools (saws, sanders, jointers, etc.) and your dust collection hoses or pipes.

- Connecting Hoses and Pipes: Joining different sections of hose or pipe to extend the reach of your system and route dust to the collector.

- Changing Direction: Allowing you to change the direction of airflow, navigating around obstacles in your workshop.

- Reducing or Increasing Diameter: Adapting to different hose sizes or tool ports with varying diameters.

- Sealing the System: Creating airtight seals to prevent dust leaks and maintain optimal airflow.

The efficiency of your entire dust collection system hinges on the quality and proper selection of these fittings. A poorly designed or installed system with inadequate fittings can lead to significant dust leakage, compromising both your health and the effectiveness of your dust collection efforts. The right 2 1/2 dust collection fittings are not just accessories; they are essential components for a safe and efficient workshop.

Common Types of 2 1/2 Dust Collection Fittings

The market offers a wide variety of 2 1/2 dust collection fittings, each designed for a specific purpose. Understanding the different types available is crucial for selecting the right fittings for your particular setup. Here are some of the most common types:

Hose Connectors

Hose connectors are the workhorses of any dust collection system. They provide a direct connection between your tools and your hoses. These fittings typically have a 2 1/2 inch outer diameter to fit the standard hose size. Some examples include:

- Straight Connectors: Used to join two hoses in a straight line.

- Elbows: Allow you to make 45-degree or 90-degree turns in your hose runs, navigating around obstacles.

- Y-Connectors: Split a single hose into two, allowing you to connect multiple tools to the same dust collection system.

- T-Connectors: Similar to Y-connectors, but with a different configuration for joining three hoses.

Adapters

Adapters are essential for connecting hoses and tools with different port sizes. These fittings typically have a 2 1/2 inch connection on one end and a different size on the other. Common types include:

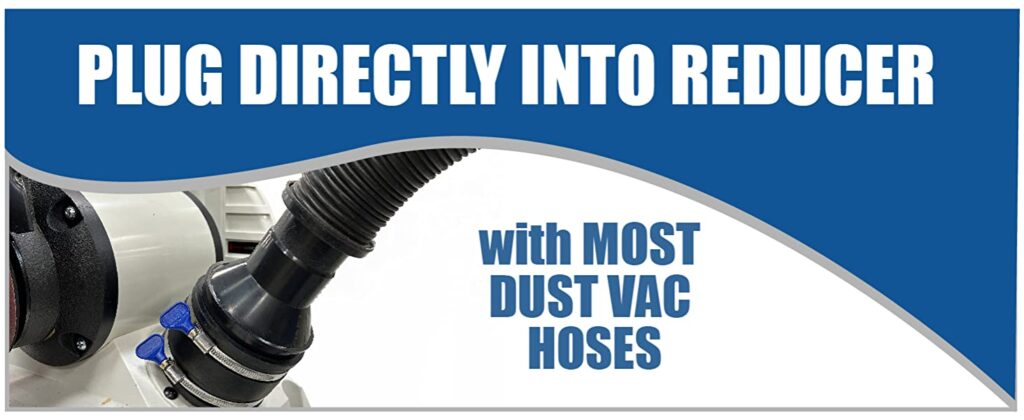

- Reducer Fittings: Reduce the diameter of a hose or pipe, allowing you to connect a larger hose to a smaller tool port.

- Increaser Fittings: Increase the diameter of a hose or pipe.

- Tool Adapters: Specifically designed to fit the dust ports of various power tools.

Blast Gates

Blast gates are critical for controlling airflow within your dust collection system. They allow you to open or close individual hose runs to direct suction to the tools you’re currently using. 2 1/2 inch blast gates are a popular choice for smaller systems or for individual tool connections.

Couplings and Clamps

These fittings are used to securely connect hoses and fittings together. They ensure airtight seals and prevent leaks. Different types include:

- Hose Clamps: Simple, adjustable clamps that tighten around the hose and fitting.

- Quick Connect Couplings: Allow for fast and easy connection and disconnection of hoses.

Materials Used in 2 1/2 Dust Collection Fittings

The material used in your 2 1/2 dust collection fittings can significantly impact their durability, performance, and longevity. Common materials include:

- Plastic: Plastic fittings are typically made of ABS (Acrylonitrile Butadiene Styrene) or PVC (Polyvinyl Chloride). They are lightweight, inexpensive, and resistant to corrosion. However, they can be prone to cracking or breaking under heavy use or impact.

- Metal: Metal fittings, often made of galvanized steel or aluminum, are significantly more durable than plastic fittings. They offer greater resistance to abrasion and impact, making them suitable for high-use environments. However, they can be more expensive and susceptible to rust if not properly coated.

- Rubber: Flexible rubber fittings are used for applications where a tight seal is required or where vibration is present.

The best material for your 2 1/2 dust collection fittings will depend on your specific needs and the demands of your workshop. Consider factors such as the type of dust you’re collecting, the frequency of use, and your budget when making your selection.

Factors to Consider When Choosing 2 1/2 Dust Collection Fittings

Selecting the right 2 1/2 dust collection fittings involves careful consideration of several factors. These considerations will ensure that your system functions efficiently and effectively.

- Compatibility: Ensure the fittings are compatible with your hoses, dust collector, and tools. Check the size and type of connections required.

- Material: Consider the material’s durability, resistance to abrasion, and overall longevity.

- Airflow: Choose fittings that minimize airflow restrictions. Smooth interior surfaces and minimal bends are crucial for optimal performance.

- Ease of Installation: Opt for fittings that are easy to install and connect. Quick-connect systems can save time and effort.

- Sealing: Ensure the fittings create airtight seals to prevent dust leaks.

- Durability: Consider the amount of use your system will receive and choose fittings that can withstand the demands of your workshop.

- Cost: Compare prices and consider the long-term value of the fittings. While inexpensive fittings may seem appealing, they may not offer the same level of performance or durability as higher-quality options.

Careful consideration of these factors will help you select 2 1/2 dust collection fittings that will meet your needs and provide years of reliable service.

Installation and Maintenance of 2 1/2 Dust Collection Fittings

Proper installation and maintenance are critical for ensuring the long-term performance and efficiency of your 2 1/2 dust collection fittings. Here are some important tips:

- Proper Fit: Ensure a snug and airtight fit between the fittings and hoses. Use clamps or couplings to secure the connections.

- Minimize Bends: Avoid sharp bends in your hose runs, as they can restrict airflow. Use elbows or flexible hoses to navigate around obstacles.

- Seal Connections: Use sealant tape or sealant paste to ensure airtight seals.

- Regular Inspection: Inspect your fittings regularly for cracks, leaks, or other signs of wear and tear.

- Cleaning: Clean your fittings periodically to remove any accumulated dust or debris. This will help maintain optimal airflow.

- Replacement: Replace any damaged or worn-out fittings promptly to prevent leaks and maintain the efficiency of your system.

Following these guidelines will help ensure your 2 1/2 dust collection fittings function effectively and contribute to a clean and healthy workshop environment.

Troubleshooting Common Issues with 2 1/2 Dust Collection Fittings

Even with the best-quality fittings, you may encounter some common issues. Here’s how to troubleshoot them:

- Dust Leaks: Check all connections for leaks. Tighten clamps or replace fittings if necessary. Use sealant tape or paste to seal any gaps.

- Reduced Airflow: Inspect the fittings for blockages or obstructions. Clear any debris that may be restricting airflow. Check for kinks or sharp bends in the hoses.

- Loose Connections: Tighten clamps or replace fittings if the connections are loose.

- Cracked or Broken Fittings: Replace any cracked or broken fittings immediately.

Regular maintenance and prompt troubleshooting will help you keep your 2 1/2 dust collection fittings in optimal working condition.

Conclusion: The Importance of the Right Fittings

In conclusion, 2 1/2 dust collection fittings are a critical component of any effective dust collection system. Choosing the right fittings, installing them properly, and maintaining them regularly is essential for ensuring a safe, healthy, and productive workshop environment. By understanding the different types of fittings available, the materials used, and the factors to consider when making your selection, you can optimize your dust collection system for peak performance.

Investing in quality 2 1/2 dust collection fittings is an investment in your health, safety, and the longevity of your tools and equipment. Don’t underestimate the importance of these small but essential components in your quest for a clean and efficient workspace.

[See also: Related Article Titles]