Mastering Press Fit Tool Plumbing: A Comprehensive Guide for Professionals and DIY Enthusiasts

The world of plumbing has undergone a significant transformation in recent years, with advancements in technology streamlining processes and enhancing efficiency. One of the most impactful innovations has been the widespread adoption of press fit tool plumbing. This method offers a faster, cleaner, and often more reliable alternative to traditional soldering or threaded connections. This article provides a comprehensive guide to press fit tool plumbing, catering to both seasoned professionals and enthusiastic DIY homeowners. We will delve into the mechanics, benefits, best practices, and considerations for successfully integrating press fit tool plumbing into your projects.

Understanding Press Fit Technology

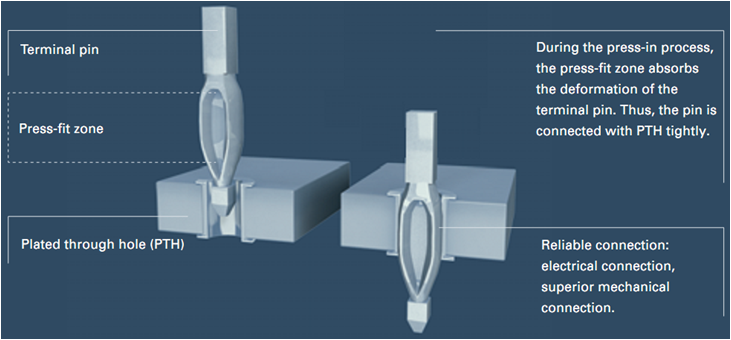

Press fit tool plumbing relies on a mechanical connection rather than heat or adhesives. The system utilizes specialized fittings and a press tool. The fittings are designed with an O-ring seal and are crimped onto the pipe using the press tool. This creates a watertight seal that is resistant to leaks and corrosion. The process is significantly faster than soldering, as it eliminates the need for heating the pipe and waiting for it to cool. It also removes the risk of open flames, making it a safer option for many applications.

The core components of a press fit tool plumbing system include:

- Press Fittings: These fittings are available in a variety of materials, including copper, stainless steel, and PEX (cross-linked polyethylene). They are designed with a precision-engineered groove to house the O-ring and a body that accepts the pipe.

- O-rings: These seals, typically made of EPDM rubber or other specialized materials, create a watertight barrier within the fitting. Their integrity is crucial to the performance of the press fit tool plumbing system.

- Press Tool: This is the workhorse of the system. It is a hydraulic or manual tool that applies the necessary force to crimp the fitting onto the pipe. Different tools are designed for various pipe sizes and fitting types.

- Pipes: Compatible pipes, like copper or PEX, are essential for the system to function correctly. Check the manufacturer’s specifications for pipe compatibility.

Benefits of Choosing Press Fit Plumbing

The advantages of using press fit tool plumbing over traditional methods are numerous and contribute to its growing popularity. These benefits include:

- Speed and Efficiency: The installation process is significantly faster than soldering or threading. This translates to reduced labor costs and quicker project completion times. A professional plumber can often complete a press fit tool plumbing job in a fraction of the time it would take using traditional methods.

- Safety: Eliminating the need for open flames makes press fit tool plumbing a safer option, particularly in confined spaces or areas with flammable materials. This reduces the risk of fire hazards and potential injuries.

- Ease of Use: The process is relatively straightforward, requiring minimal training compared to soldering. This makes it an attractive option for both professional plumbers and DIY enthusiasts.

- Reliability: The mechanical connection created by the press tool provides a strong, leak-resistant seal. The O-ring technology ensures a long-lasting and durable connection.

- Versatility: Press fit tool plumbing is compatible with a wide range of pipe materials, including copper, stainless steel, and PEX. This versatility allows for its use in a variety of plumbing applications.

- Reduced Risk of Leaks: The consistent and precise nature of the pressing process minimizes the risk of leaks compared to soldering, which can be prone to human error.

Step-by-Step Guide to Using a Press Fit Tool

While the process is relatively simple, following the correct steps is crucial for ensuring a successful and leak-free installation. Here’s a step-by-step guide:

- Preparation: Begin by cutting the pipe to the desired length using a pipe cutter. Ensure a clean, square cut. Remove any burrs or sharp edges from the pipe end using a deburring tool. This is critical for a proper seal.

- Cleaning: Thoroughly clean the pipe end and the inside of the fitting using a wire brush or abrasive pad. Remove any dirt, debris, or oxidation. This ensures a proper seal between the pipe and the fitting.

- Assembly: Insert the pipe into the fitting until it reaches the stop. Ensure the pipe is fully inserted to the correct depth.

- Pressing: Place the jaws of the press tool over the fitting. Ensure the jaws are correctly aligned and of the correct size for the fitting. Activate the press tool, following the manufacturer’s instructions. The tool will crimp the fitting onto the pipe, creating the seal.

- Inspection: After pressing, inspect the fitting to ensure it is properly crimped. Check for any gaps or deformities. Some fittings have visual indicators to confirm a successful press.

Choosing the Right Press Fit Tool

Selecting the appropriate press fit tool is crucial for ensuring the success of your project. Several factors should be considered:

- Pipe Size Compatibility: Ensure the tool is compatible with the pipe sizes you will be using. Tools are typically designed for specific size ranges.

- Material Compatibility: Some tools are designed for specific materials. Make sure the tool is compatible with the fittings and pipe materials you are using (e.g., copper, stainless steel, PEX).

- Power Source: Press tools can be manual (lever-operated), hydraulic (battery-powered or electric), or powered by other means. Hydraulic tools are generally preferred for larger jobs due to their speed and ease of use. Manual tools are suitable for smaller jobs and offer portability.

- Brand Reputation and Reliability: Choose a reputable brand known for producing high-quality and reliable tools. Research reviews and ratings before making a purchase.

- Features: Consider features such as automatic shut-off, LED lights, and tool head rotation for enhanced usability.

Troubleshooting Common Press Fit Plumbing Issues

While press fit tool plumbing is generally reliable, issues can arise. Here are some common problems and their solutions:

- Leaks: The most common issue is leaks. These can occur due to improper crimping, debris in the fitting, or damaged O-rings. Ensure the pipe is fully inserted into the fitting, the tool is properly aligned, and the crimp is complete. Replace any damaged fittings or O-rings.

- Incomplete Crimp: If the tool fails to complete the crimp, check the battery (for hydraulic tools), ensure the tool is properly calibrated, and verify that the fitting is properly positioned.

- Corrosion: While press fit tool plumbing is resistant to corrosion, it can still occur if incompatible materials are used or if the system is exposed to harsh chemicals. Ensure all materials are compatible and follow manufacturer’s recommendations.

- Difficulty Removing Fittings: Once pressed, fittings are designed to be permanent. However, if removal is necessary, specialized tools are available to remove them.

Press Fit Plumbing vs. Traditional Methods

Comparing press fit tool plumbing to traditional methods like soldering or threaded connections reveals several key differences:

- Speed: Press fit tool plumbing is significantly faster. Soldering can take considerably longer due to the need for heating, cooling, and cleaning. Threaded connections can be time-consuming to assemble and require careful application of thread sealant.

- Skill Level: Press fit tool plumbing requires less specialized skill than soldering. Soldering requires proficiency in using a torch and achieving a proper solder joint. Threaded connections require precise alignment and application of sealant.

- Safety: Press fit tool plumbing eliminates the hazards associated with open flames, making it safer. Soldering presents a risk of fire and burns.

- Cost: While the initial investment in a press tool can be significant, press fit tool plumbing can reduce labor costs over time. The cost of fittings may be slightly higher than traditional fittings.

- Reliability: Press fit tool plumbing offers a consistent and reliable connection, minimizing the risk of leaks. The quality of a solder joint depends on the skill of the plumber. Threaded connections can loosen over time.

Best Practices for Press Fit Tool Plumbing

To ensure optimal results with press fit tool plumbing, adhere to these best practices:

- Read the Manufacturer’s Instructions: Always follow the manufacturer’s instructions for the press tool and fittings.

- Use the Correct Tools and Fittings: Ensure the tools and fittings are compatible with the pipe material and size.

- Prepare the Pipe Properly: Cut the pipe squarely, deburr the ends, and thoroughly clean the pipe and fittings.

- Inspect Fittings Before Use: Check for any damage to the O-rings or the fitting body.

- Properly Align the Press Tool: Ensure the jaws of the press tool are correctly aligned on the fitting.

- Complete the Crimp: Make sure the press tool completes the crimp cycle.

- Inspect the Finished Connection: Visually inspect the finished connection to ensure it is properly crimped and there are no gaps.

- Test the System: After installation, test the system for leaks by pressurizing the lines.

The Future of Press Fit Tool Plumbing

Press fit tool plumbing is poised for continued growth and innovation. Advancements in materials, tool technology, and fitting designs are expected to further enhance the efficiency, reliability, and versatility of the system. As the industry evolves, professionals and DIY enthusiasts alike will benefit from these advancements. The ongoing focus on safety, ease of use, and reduced installation times makes press fit tool plumbing an attractive and increasingly prevalent choice for plumbing applications.

The benefits of press fit tool plumbing are clear: speed, safety, and reliability. As this technology continues to evolve, it will likely become even more integrated into both residential and commercial plumbing projects. Understanding the fundamentals of press fit tool plumbing, from the mechanics of the tool to the installation process, is key to mastering this modern approach to plumbing. By following best practices and staying informed about industry advancements, plumbers and homeowners can ensure successful and long-lasting plumbing installations.

For those looking to expand their knowledge of plumbing, consider [See also: Plumbing Certifications: Your Path to Professionalism] or [See also: The Ultimate Guide to PEX Piping for Homeowners].

Press fit tool plumbing is a rapidly evolving field. Staying up-to-date on the latest tools, fittings, and techniques is crucial for anyone working in the plumbing industry or undertaking DIY projects. Continuous learning and adaptation are key to success in this dynamic environment. As technology progresses, it will be interesting to see what further innovations and improvements are made to press fit tool plumbing systems.