Fuel Tank Repair: A Step-by-Step Video Tutorial – Navigating the Challenges

The fuel tank: a seemingly simple component, yet a vital one in the intricate dance of internal combustion. When it falters, the symphony of a smooth-running engine turns into a cacophony of sputtering and stalling. This article delves into the often-daunting world of fuel tank repair, offering a clear, concise, and step-by-step guide, supplemented by the invaluable resource of a video tutorial. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding the intricacies of fuel tank repair is crucial for maintaining your vehicle’s longevity and performance.

The purpose of this guide is to demystify the process, providing a roadmap for identifying issues, gathering the necessary tools, and executing the fuel tank repair with confidence. We’ll cover everything from diagnosing leaks and identifying corrosion to the actual repair procedures, emphasizing safety and best practices throughout. The inclusion of a video tutorial ensures that the information is not just theoretical; it’s practical, visual, and readily accessible.

Understanding Fuel Tank Issues: Diagnosis is Key

Before diving into the repair itself, a thorough diagnosis is paramount. A misdiagnosis can lead to wasted time, money, and potentially, further damage. Common problems affecting fuel tanks include:

- Leaks: These can range from small drips to significant fuel loss, often caused by corrosion, physical damage, or faulty seals. The location of the leak is critical in determining the repair method.

- Corrosion: Rust and corrosion are the enemies of any metal component, and fuel tanks are no exception. Internal corrosion can contaminate the fuel system, while external corrosion can weaken the tank’s structure, leading to leaks.

- Damage from Impact: Accidents or road debris can cause dents, punctures, or even complete tank rupture.

- Fuel Pump Failure: Although not a repair of the tank itself, a failing fuel pump can mimic fuel tank problems, leading to misdiagnosis.

- Fuel Level Sensor Malfunctions: These can provide inaccurate fuel level readings, causing confusion about the fuel tank’s actual state.

The first step is to visually inspect the fuel tank. Look for obvious signs of leaks, rust, or physical damage. Sniff for the telltale odor of gasoline. Check for wetness around seams, fittings, and the fuel pump. If a leak is suspected, try to determine its source. Consider using a flashlight to illuminate hard-to-reach areas. If a leak is present, it’s imperative to address it immediately to prevent fire hazards and environmental damage.

Safety First: Essential Precautions for Fuel Tank Repair

Working with flammable liquids like gasoline demands a strict adherence to safety protocols. Failure to do so can result in severe injury or even death. Before initiating any fuel tank repair, always:

- Disconnect the Battery: This prevents accidental sparks that could ignite fuel vapors.

- Work in a Well-Ventilated Area: Gasoline fumes are toxic and can accumulate rapidly in enclosed spaces. Ensure adequate ventilation to dissipate these fumes.

- Wear Protective Gear: This includes safety glasses, gloves resistant to gasoline, and appropriate clothing. Avoid loose clothing that could snag on equipment.

- Have a Fire Extinguisher Ready: Keep a Class B fire extinguisher (designed for flammable liquids) readily accessible.

- Avoid Open Flames and Sparks: Refrain from smoking, welding, or using any device that could generate sparks near the fuel tank.

- Drain the Fuel Tank: Before commencing any repair, drain as much fuel as possible. Use a siphon or a fuel pump to extract the fuel into an approved container. Dispose of the fuel responsibly according to local regulations.

Ignoring these safety precautions can have devastating consequences. Always prioritize safety above all else.

Gathering Your Tools: The Arsenal for Fuel Tank Repair

The specific tools required will vary depending on the nature of the repair. However, some essential tools are consistently needed for fuel tank repair:

- Jack and Jack Stands: To safely lift and support the vehicle.

- Wrench Set and Socket Set: Metric and/or SAE, depending on your vehicle.

- Screwdrivers: Various sizes and types (flathead and Phillips head).

- Pliers: For gripping and manipulating components.

- Fuel Line Disconnect Tool: For safely disconnecting fuel lines without damaging them.

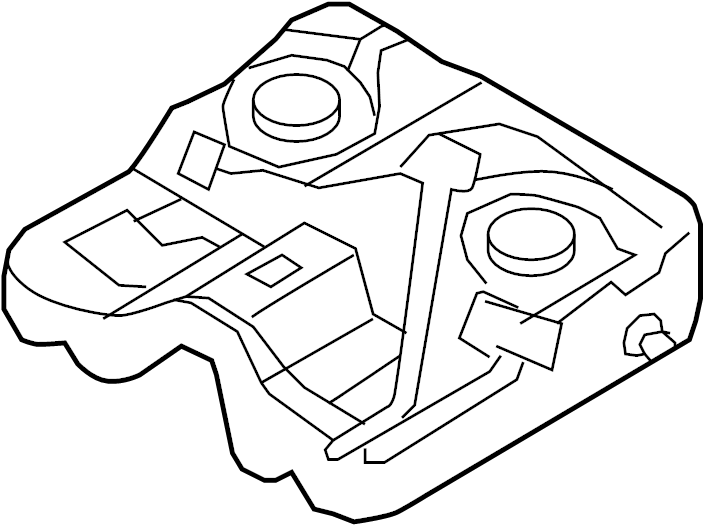

- Fuel Tank Repair Kit: Includes epoxy, sealant, and other necessary materials.

- Wire Brush: For cleaning rust and corrosion.

- Sandpaper: Various grits for preparing the surface for repair.

- Safety Glasses and Gloves: For personal protection.

- Flashlight: For illuminating the work area.

- Drain Pan: For collecting any remaining fuel.

- Fuel-Resistant Gloves: Protect your hands from gasoline exposure.

The availability of these tools is crucial for a successful fuel tank repair. Make sure you have everything you need before starting the process.

Step-by-Step Fuel Tank Repair Guide (with Video Tutorial Reference)

The following steps provide a general guide to fuel tank repair. Specific procedures may vary depending on the vehicle make and model. Refer to the included video tutorial for a visual demonstration and specific instructions tailored to common scenarios. Remember to always consult your vehicle’s repair manual for detailed instructions.

- Preparation: Park the vehicle on a level surface, engage the parking brake, and disconnect the negative battery terminal. Ensure the work area is well-ventilated and free from ignition sources. Drain the fuel tank as completely as possible.

- Locate the Fuel Tank: Determine the location of the fuel tank. This is usually under the rear of the vehicle, but it can vary. Consult your vehicle’s repair manual if necessary.

- Access the Fuel Tank: Depending on the vehicle, you may need to raise it using a jack and jack stands. Identify and disconnect any electrical connectors, fuel lines, and vent lines connected to the fuel tank.

- Remove the Fuel Tank (If Necessary): In some cases, the repair can be performed with the tank in place. However, for more extensive repairs, it may be necessary to remove the tank. Support the tank with a jack or a transmission jack, unbolt the straps or mounting hardware, and carefully lower the tank.

- Clean the Affected Area: Use a wire brush and sandpaper to remove rust, corrosion, and any loose debris from the area to be repaired. Clean the surface thoroughly with a degreaser and allow it to dry completely.

- Assess the Damage: Evaluate the extent of the damage. For small leaks or minor corrosion, a fuel tank repair kit may suffice. For more significant damage, consider replacing the tank.

- Apply the Repair (Using a Fuel Tank Repair Kit): Follow the instructions provided with the repair kit. This typically involves applying a sealant or epoxy to the damaged area. Ensure the sealant covers the entire affected area and forms a watertight seal.

- Allow the Repair to Cure: Allow the sealant or epoxy to cure completely, according to the manufacturer’s instructions. This may take several hours or even overnight.

- Reinstall the Fuel Tank (If Removed): Carefully lift the tank back into position and secure it with the mounting hardware. Reconnect all fuel lines, electrical connectors, and vent lines.

- Test for Leaks: Refill the fuel tank with fuel and carefully inspect the repaired area for any leaks. Start the engine and check for leaks while the fuel system is pressurized.

- Final Inspection: After confirming there are no leaks, lower the vehicle and inspect all connections for any signs of fuel leakage.

Video Tutorial Integration: The video tutorial should visually demonstrate these steps, providing clear guidance on each stage of the fuel tank repair process. The video should offer close-up shots of the repair process, emphasizing the correct application of sealant, the removal of corrosion, and the safe handling of fuel lines.

Fuel Tank Replacement: When Repair Isn’t Enough

While fuel tank repair can often be a viable solution, there are instances where replacement is the only practical option. This includes situations where:

- The Tank is Severely Corroded: Extensive corrosion can compromise the tank’s structural integrity, making repair unreliable.

- The Damage is Extensive: Large punctures or multiple leaks may be too difficult or costly to repair effectively.

- The Tank Has Been Involved in a Collision: Significant impact damage can compromise the tank’s safety and performance.

- Repair Costs Exceed Replacement Costs: In some cases, the cost of a fuel tank repair, including materials and labor, may approach or exceed the cost of a new tank.

Replacing a fuel tank is a more involved process than a simple repair. It involves removing the old tank, installing the new tank, and connecting all fuel lines and electrical components. It’s important to ensure the new tank is compatible with your vehicle’s make and model. Refer to your vehicle’s repair manual for specific instructions on fuel tank replacement. Consider consulting a professional mechanic if you are not comfortable with this procedure.

Preventative Maintenance: Extending the Life of Your Fuel Tank

Prevention is often the best medicine. Several preventative measures can help extend the life of your fuel tank and minimize the need for fuel tank repair:

- Regular Inspections: Periodically inspect your fuel tank for signs of leaks, corrosion, or damage.

- Use Quality Fuel: Avoid using fuel that contains excessive water or contaminants, as these can accelerate corrosion.

- Park in a Covered Area: Shielding your vehicle from the elements can help prevent rust and corrosion.

- Address Corrosion Promptly: If you notice any rust or corrosion, address it immediately to prevent it from spreading.

- Avoid Overfilling the Tank: Overfilling the tank can damage the fuel system and potentially cause leaks.

By taking these preventative measures, you can significantly reduce the likelihood of encountering fuel tank repair issues.

Conclusion: Mastering Fuel Tank Repair with Confidence

Fuel tank repair may seem daunting, but with the right knowledge, tools, and a clear step-by-step guide, it’s a task that many DIY enthusiasts can successfully undertake. This article, coupled with the visual aid of the video tutorial, provides a comprehensive resource for tackling common fuel tank problems. Remember to prioritize safety, follow the instructions carefully, and always consult your vehicle’s repair manual for specific guidance. By understanding the process and taking the necessary precautions, you can keep your vehicle running smoothly and avoid costly repairs in the long run. The ability to perform fuel tank repair empowers you to take control of your vehicle’s maintenance and potentially save money. [See also: How to Diagnose Car Problems] [See also: Automotive Maintenance Guide] [See also: Best Fuel Additives]

This guide aims to equip you with the knowledge and confidence to approach fuel tank repair with a proactive mindset. The information provided is intended for informational purposes and should not be considered a substitute for professional advice. Always consult a qualified mechanic if you are unsure about any aspect of the repair process.