Decoding the ABS Wheel Speed Sensor: Direct Fit, Factory Quantity, and Wire Configuration

The automotive world is a complex tapestry of interconnected systems, each playing a crucial role in ensuring a safe and efficient driving experience. Among these systems, the Anti-lock Braking System (ABS) stands out as a critical safety feature, preventing wheel lockup during braking and allowing drivers to maintain steering control. A cornerstone of the ABS is the ABS wheel speed sensor. This article delves into the intricacies of these sensors, focusing on the often-sought-after specifications: direct fit, factory quantity, and the all-important wire configuration.

The phrase “ABS wheel speed sensor with factory quantity wire direct fit” isn’t just a collection of words; it represents a specific product profile sought by both professional mechanics and DIY enthusiasts. It highlights the desire for a replacement part that seamlessly integrates with a vehicle’s existing systems, mirroring the original equipment manufacturer (OEM) specifications. This article will break down the significance of each component of this description.

The Crucial Role of the ABS Wheel Speed Sensor

The ABS wheel speed sensor is, at its core, a data-gathering device. It’s responsible for monitoring the rotational speed of each wheel. This information is relayed to the ABS control module, a central processing unit that makes critical decisions about brake pressure during emergency braking scenarios. By comparing the speeds of each wheel, the ABS module can detect when a wheel is about to lock up. When this happens, the module rapidly pulses the brakes, preventing the wheel from skidding and allowing the driver to maintain control.

Without functioning ABS wheel speed sensors, the ABS system is rendered inoperative. While the vehicle’s standard braking system will still function, the crucial safety benefits of ABS – the ability to steer during hard braking and prevent skidding – are lost. This underscores the importance of maintaining these sensors in optimal working condition.

Understanding “Direct Fit”

The term “direct fit” is a key selling point for any replacement part. It signifies that the ABS wheel speed sensor is designed to be a plug-and-play replacement for the original sensor. This means that the sensor is manufactured to the exact specifications of the OEM part, including dimensions, mounting points, and connector type. A direct fit sensor eliminates the need for modifications or adaptations during installation, simplifying the repair process and saving valuable time.

Choosing a direct fit ABS wheel speed sensor offers several advantages. Firstly, it ensures a proper and secure installation, minimizing the risk of malfunctions caused by an improperly fitted part. Secondly, it guarantees compatibility with the vehicle’s existing ABS system, preventing potential errors or performance issues. Finally, a direct fit sensor often comes with all the necessary hardware, such as mounting brackets and connectors, further streamlining the installation process.

The Significance of “Factory Quantity”

“Factory quantity” refers to the specifications of the original equipment manufacturer (OEM) part. When a sensor is described as having “factory quantity” characteristics, it implies that the sensor is made to the same standards, materials, and performance characteristics as the original sensor installed at the factory. This is a crucial factor, as it ensures the replacement sensor will function as intended, providing the same level of accuracy and reliability as the original.

The implications of using a sensor that doesn’t meet factory quantity specifications can be significant. A sensor that is not up to the required standards may provide inaccurate readings, potentially causing the ABS system to malfunction. This could manifest as premature ABS activation, delayed braking response, or even complete system failure. Choosing a sensor with factory quantity specifications minimizes these risks and ensures the ABS system functions as designed.

Deciphering the Wire Configuration

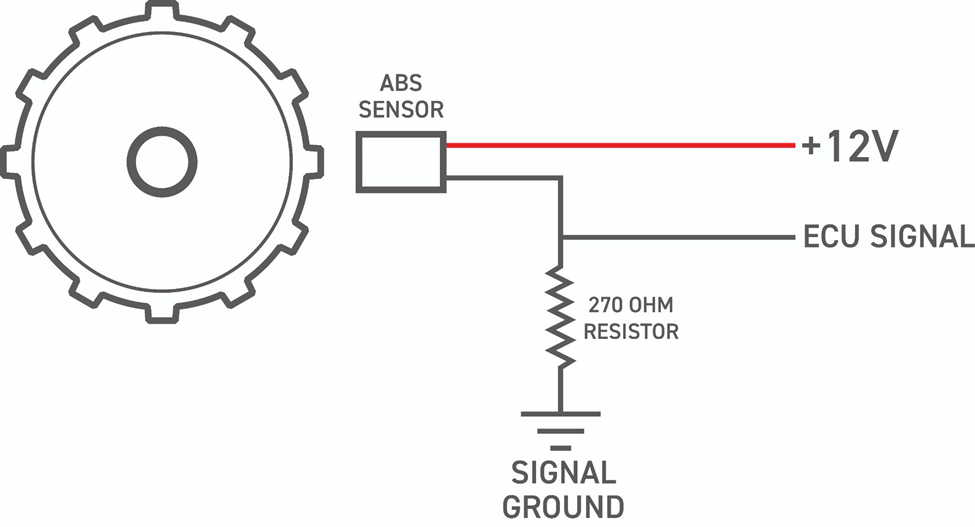

The “wire configuration” of an ABS wheel speed sensor is a critical aspect that directly impacts its compatibility and functionality. The number of wires, their colors, and their connection type must match the original sensor for the replacement to work correctly. This information is crucial for a successful installation and to prevent potential electrical problems.

ABS wheel speed sensors typically use either two-wire or three-wire configurations, although some may have more. The number of wires often correlates with the type of sensor technology used. Two-wire sensors are commonly passive sensors, which generate a signal based on the rotation of a toothed wheel. Three-wire sensors are often active sensors, which require a power supply to operate and provide a more precise signal.

When purchasing an ABS wheel speed sensor, it is essential to verify the wire configuration. Comparing the old sensor’s wire configuration with the new sensor’s specifications is critical. Ensuring that the connector type and pin arrangement match is also vital. Failure to match the wire configuration can result in the new sensor not working, or even damaging the vehicle’s electrical system. Always consult the vehicle’s repair manual or a qualified mechanic if you’re unsure about the correct wire configuration.

Installation: A Step-by-Step Guide

While the exact installation procedure can vary slightly depending on the vehicle make and model, the general steps for replacing an ABS wheel speed sensor with a direct fit, factory quantity sensor are as follows:

- Preparation: Park the vehicle on a level surface, engage the parking brake, and disconnect the negative battery terminal. Gather the necessary tools, including a jack, jack stands, wrenches, screwdrivers, and a multimeter.

- Wheel Removal: Loosen the lug nuts on the wheel where the sensor is being replaced. Raise the vehicle with a jack and secure it on jack stands. Remove the wheel.

- Sensor Location: Locate the ABS wheel speed sensor. It is typically found near the wheel hub or brake rotor.

- Disconnecting the Old Sensor: Disconnect the electrical connector from the old sensor. This may require squeezing a retaining clip or using a small screwdriver to release it.

- Removing the Old Sensor: Remove the old sensor from its mounting location. This may involve removing a bolt or screws.

- Installing the New Sensor: Install the new direct fit ABS wheel speed sensor in the same location, securing it with the appropriate fasteners.

- Connecting the New Sensor: Connect the electrical connector to the new sensor, ensuring it is securely attached.

- Reassembling the Wheel: Reinstall the wheel and tighten the lug nuts.

- Testing the System: Reconnect the negative battery terminal. Start the vehicle and check for any ABS warning lights on the dashboard. If the light is off, the installation was successful. If the light remains on, there may be a problem with the installation or the new sensor. In such cases, consult a qualified mechanic.

Troubleshooting Common Issues

Even with a direct fit ABS wheel speed sensor, problems can sometimes arise. Here are some common issues and troubleshooting tips:

- ABS Warning Light: If the ABS warning light remains on after installation, double-check all connections. Ensure the sensor is properly seated and the connector is fully engaged. Check the sensor’s wire configuration against the original to ensure they match.

- Inaccurate Readings: If the ABS system is activating prematurely or the braking performance feels erratic, there might be a problem with the sensor’s signal. Inspect the toothed wheel (reluctor ring) for any damage or debris.

- Sensor Failure: Occasionally, a new sensor may be faulty. If all other troubleshooting steps fail, consider replacing the sensor with another direct fit, factory quantity unit from a reputable supplier.

- Wiring Damage: Inspect the wiring harness for any damage, such as cuts or frayed wires. Repair any damaged wiring or replace the harness if necessary. The correct wire configuration is paramount.

Choosing the Right ABS Wheel Speed Sensor

Selecting the correct ABS wheel speed sensor is crucial for the safety and proper functioning of the vehicle’s braking system. Here are some key considerations:

- Vehicle Year, Make, and Model: Always verify that the sensor is compatible with the vehicle’s specific year, make, and model. Use online parts catalogs or consult with a parts specialist to ensure a proper fit.

- Direct Fit Guarantee: Prioritize sensors advertised as “direct fit.” This ensures easy installation and compatibility.

- Factory Quantity Specifications: Opt for sensors that meet factory quantity specifications. This guarantees the sensor will perform as intended.

- Wire Configuration: Carefully check the wire configuration of the new sensor to ensure it matches the original.

- Reputable Suppliers: Purchase sensors from reputable suppliers to ensure quality and reliability.

- Warranty: Look for sensors with a warranty to protect against defects.

Conclusion: Prioritizing Safety and Performance

The ABS wheel speed sensor is a vital component of a modern vehicle’s safety system. Choosing the right replacement sensor, especially one that is a direct fit, meets factory quantity specifications, and has the correct wire configuration, is essential for maintaining optimal braking performance and ensuring driver safety. By understanding the role of the sensor, the importance of these specifications, and the installation process, drivers and mechanics alike can confidently replace faulty sensors and keep their vehicles running safely.

The information provided in this article is for informational purposes only and does not constitute professional advice. Always consult a qualified mechanic for vehicle repairs and maintenance. [See also: Diagnosing ABS System Problems] [See also: Common ABS Sensor Failures] [See also: The Science Behind Anti-lock Brakes] [See also: Choosing the Right Brake Pads] [See also: Understanding Brake Rotor Wear] [See also: ABS Warning Light Troubleshooting]