Priming Your Engine: Essential Oil Pump Priming Tools and Techniques for Optimal Performance

The heart of any internal combustion engine is its lubrication system. This intricate network of passages and components relies on the oil pump to circulate lifeblood – oil – throughout the engine. Ensuring the oil pump functions correctly from the very start is crucial for preventing catastrophic engine damage. This article delves into the critical process of oil pump priming tools and techniques, providing a comprehensive guide for both seasoned mechanics and enthusiastic DIYers.

The initial startup of a newly assembled or rebuilt engine is a vulnerable moment. Without adequate lubrication, friction can quickly lead to wear and tear, potentially causing severe damage within seconds. This is where the importance of oil pump priming becomes paramount. By priming the oil pump before the first ignition, you guarantee that oil is immediately available to critical engine components, minimizing the risk of dry starts and ensuring optimal performance.

Understanding the Role of the Oil Pump

The oil pump’s primary function is to draw oil from the oil pan (sump) and distribute it under pressure to various parts of the engine. This pressurized oil lubricates moving parts like the crankshaft, connecting rods, camshaft, and valve train, reducing friction and heat. The oil also serves as a coolant, carrying away heat generated by combustion and friction. Furthermore, the oil helps to clean the engine by carrying away contaminants like dirt, carbon deposits, and metal shavings, which are then filtered out by the oil filter.

Different types of oil pumps exist, including gear pumps, rotor pumps, and vane pumps. Regardless of the design, they all operate on the same principle: creating a vacuum to draw oil into the pump and then pressurizing it for distribution. The efficiency and effectiveness of the oil pump directly impact the engine’s lifespan and overall performance. Failure of the oil pump can lead to rapid engine failure.

Why Priming is Essential

During engine assembly or after an oil change, the oil pump and the lubrication system are often dry. This means that the pump needs to be filled with oil before it can effectively circulate it throughout the engine. Starting the engine without priming the oil pump can result in a dry start, where critical engine components are starved of lubrication. This can lead to:

- Excessive wear and tear on bearings and other moving parts.

- Scoring of cylinder walls.

- Damage to the camshaft and valve train.

- Premature engine failure.

Priming the oil pump ensures that oil is immediately available to all critical engine components, minimizing the risk of these damaging effects. It’s a proactive measure that can significantly extend the life of your engine and prevent costly repairs.

Essential Tools for Oil Pump Priming

Several oil pump priming tools are available, ranging from simple DIY solutions to specialized professional equipment. The choice of tool often depends on the type of engine and the level of access to the oil pump. Here are some of the most common and effective oil pump priming tools:

The Priming Tool

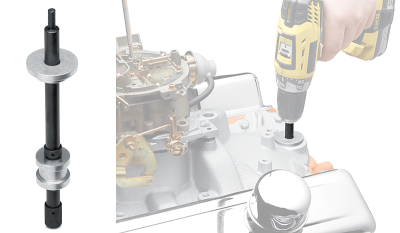

The most common and often recommended oil pump priming tool is a dedicated priming tool. This is typically a shaft that fits into the oil pump’s drive, allowing you to manually rotate the pump and draw oil into the system. These tools come in various sizes and configurations to fit different engine designs. They are often made of durable materials like steel and feature a handle for easy rotation.

The Drill-Powered Priming Tool

For convenience and speed, many mechanics prefer a drill-powered priming tool. This tool attaches to a standard power drill, allowing you to rotate the oil pump quickly and efficiently. This is particularly useful for engines where access to the oil pump is limited. Ensure the drill is set to a low speed to avoid damaging the oil pump or other engine components. Using a drill offers a faster way to prime the oil pump and fill the system with oil.

The Oil Filter Priming Method

Some mechanics use the oil filter as a point of entry for priming. By filling the oil filter with fresh oil before installation and then rotating the engine by hand or using a starter motor (with the ignition disabled), they can help to draw oil into the pump and the lubrication system. This method is less precise but can be effective, especially when other tools are unavailable. However, you must always ensure the oil filter is properly installed and sealed to prevent leaks.

Step-by-Step Priming Techniques

The specific techniques for priming the oil pump may vary depending on the engine type and the tools available. However, the general principles remain the same. Here’s a step-by-step guide to help you prime your oil pump effectively:

- Prepare the Engine: Ensure the engine is properly assembled and ready for startup. Install the oil filter and fill it with fresh oil (if using this method). Make sure the oil pan is filled with the correct type and amount of oil.

- Locate the Oil Pump Drive: Identify the location of the oil pump drive on your engine. This is typically where the distributor would be located or a specific access point.

- Insert the Priming Tool: Insert the priming tool into the oil pump drive. Ensure it fits securely and engages with the pump’s drive shaft.

- Rotate the Oil Pump: Rotate the priming tool manually or with a drill. Rotate the pump until you see oil pressure build up on the oil pressure gauge or until oil begins to flow freely from the oil galleys. This indicates that the pump is primed and circulating oil. The time required can vary, depending on the engine.

- Verify Oil Pressure: Monitor the oil pressure gauge during the priming process. You should see a gradual increase in pressure as the oil pump fills the system.

- Reinstall Components: Once the oil pump is primed, remove the priming tool and reinstall any components that were removed for access.

- Start the Engine (with caution): Start the engine and allow it to idle for a few minutes. Monitor the oil pressure gauge closely for any fluctuations or drops in pressure.

- Check for Leaks: After the engine has run for a few minutes, check for any oil leaks around the oil filter, oil pan, and other areas of the engine.

Remember to consult your engine’s service manual for specific instructions and recommendations for priming the oil pump. The manual often provides the best guidance for your specific engine model.

Common Mistakes to Avoid

While oil pump priming is a relatively straightforward process, several common mistakes can prevent it from working effectively. Avoiding these pitfalls can help you ensure that your engine receives proper lubrication from the start.

- Using the Wrong Priming Tool: Ensure you are using the correct priming tool for your engine. Using an incompatible tool can damage the oil pump or prevent it from priming correctly.

- Not Rotating the Pump Long Enough: Be patient. It may take several minutes of rotating the oil pump to fully prime the system, especially in a newly assembled engine.

- Neglecting to Check Oil Pressure: Always monitor the oil pressure gauge during the priming process. This is a crucial indicator of whether the pump is working correctly.

- Starting the Engine Too Soon: Avoid starting the engine until you have confirmed that oil pressure is building and that oil is circulating throughout the system.

- Ignoring the Service Manual: Always refer to your engine’s service manual for specific instructions and recommendations.

Advanced Considerations

For high-performance engines or engines that have been heavily modified, additional considerations may be necessary when priming the oil pump. This includes:

- Using a Pre-Oiler: A pre-oiler is a device that pumps oil into the engine’s lubrication system before the engine is started. This can provide even greater protection against dry starts, particularly in engines with tight tolerances or high-performance components.

- Checking Oil Galley Plugs: Ensure that all oil galley plugs are properly installed and sealed to prevent oil leaks and maintain proper oil pressure.

- Considering Oil Viscosity: The viscosity of the oil can affect the priming process. Using the correct oil viscosity for your engine is crucial for proper lubrication.

Conclusion: Ensuring Engine Longevity with Proper Priming

Oil pump priming is a critical step in the engine assembly or after an oil change process. By understanding the importance of priming, utilizing the right tools, and following the correct techniques, you can significantly reduce the risk of engine damage and ensure optimal performance. By taking the time to prime the oil pump, you are investing in the long-term health and longevity of your engine. This preventative measure is a small price to pay for the peace of mind that comes with knowing your engine is properly lubricated from the moment it starts. Don’t underestimate the power of proper oil pump priming; it’s the foundation for a healthy and reliable engine.

[See also: Engine Oil Types and Grades]

[See also: How to Diagnose Low Oil Pressure]

[See also: The Importance of Regular Oil Changes]