Mastering Timing Belt Clamp Tightening: A Step-by-Step Guide to Precision

The timing belt, a seemingly humble component, plays a critical role in the harmonious operation of your vehicle’s engine. It synchronizes the crankshaft and camshaft, ensuring the valves open and close at the precise moments required for optimal combustion. Failure of this belt can lead to catastrophic engine damage, making its maintenance and, crucially, the correct tightening of its related components paramount. This comprehensive guide delves into the intricacies of timing belt clamp tightening, providing a step-by-step approach to ensure accuracy and longevity. Understanding and mastering timing belt clamp tightening is essential for any DIY enthusiast or professional mechanic.

The Importance of Precise Tightening

The timing belt clamp tightening process is not merely about applying force; it’s about achieving the correct tension. Over-tightening can prematurely wear down the belt and related components like the water pump and tensioner. Conversely, under-tightening can lead to slippage, disrupting the engine’s timing and potentially causing severe damage. The correct tension is crucial for the proper function of the timing belt. The timing belt clamp, often overlooked, is a vital part of this process because it directly impacts the tension applied to the belt itself. Therefore, understanding the nuances of timing belt clamp tightening is essential for engine health.

Tools and Materials You’ll Need

Before embarking on this task, gather the necessary tools and materials. Having everything prepared beforehand will streamline the process and minimize potential delays. This includes:

- A new timing belt: Always replace the belt when performing this procedure.

- A new timing belt tensioner: These are often replaced concurrently with the belt.

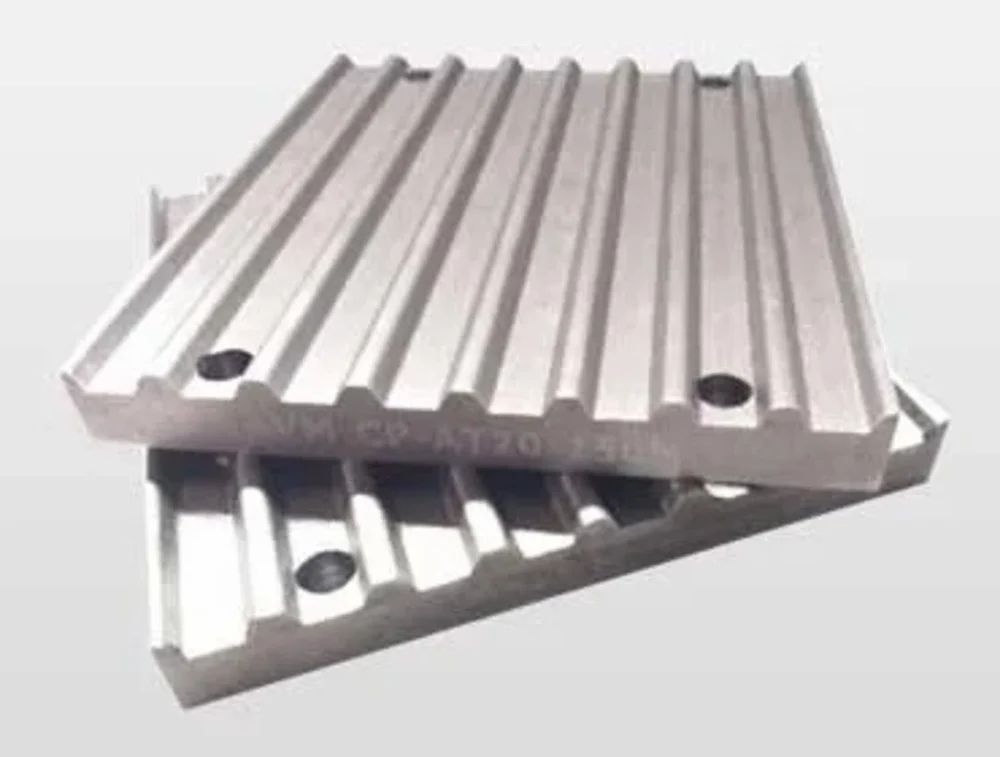

- A timing belt clamp (specific to your vehicle’s engine): Ensure you have the correct clamp for your engine.

- A torque wrench: Essential for accurate tightening.

- Sockets and wrenches: A comprehensive set is beneficial.

- A jack and jack stands: For safely lifting and supporting the vehicle.

- Wheel chocks: For added safety.

- A repair manual specific to your vehicle: Provides crucial specifications and torque values.

- Gloves and safety glasses: For protection.

- Penetrating oil (optional): For loosening stubborn bolts.

Preparing Your Vehicle for the Job

Safety is paramount. Begin by parking your vehicle on a level surface and engaging the parking brake. Chock the rear wheels for added security. Then, jack up the vehicle and securely place it on jack stands. Consult your vehicle’s repair manual for the specific jacking points. Disconnect the negative battery cable to prevent any accidental electrical shorts. Access to the timing belt will usually require removing components such as the front wheels, splash shields, and potentially other engine accessories like the serpentine belt and its tensioner. Carefully document the removal process, taking photos or making notes to aid in reassembly.

Step-by-Step Guide to Timing Belt Clamp Tightening

This section provides a detailed, step-by-step guide to the timing belt clamp tightening procedure. Remember, always consult your vehicle’s repair manual for specific instructions and torque specifications, as these can vary significantly between different makes and models. The following steps provide a general overview.

- Locate the Timing Belt and Components: Once you’ve removed the necessary components to expose the timing belt, locate the belt, tensioner, and any relevant pulleys.

- Loosen the Tensioner: The tensioner is typically held in place by a bolt or nut. Loosen this bolt or nut to release the tension on the old timing belt. Some tensioners may require a special tool to compress them.

- Remove the Old Belt: Carefully remove the old timing belt. Note the direction of rotation, as some belts have directional arrows.

- Install the New Belt: Align the new timing belt with the crankshaft pulley and camshaft pulleys. Ensure the belt teeth mesh correctly with the pulleys. Refer to your repair manual for specific alignment marks or procedures.

- Install the Tensioner: Install a new tensioner if one is included in your kit.

- Tighten the Tensioner (Preliminary): Tighten the tensioner bolt or nut to the manufacturer’s specified torque value, but typically not the final torque.

- Adjusting the Timing Belt Clamp: This is where the timing belt clamp tightening comes into play. The clamp may be integrated into the tensioner or be a separate component. The repair manual should detail the specific method for your vehicle. This might involve rotating the engine and using a specialized tool to measure the belt deflection.

- Tighten the Timing Belt Clamp to Specifications: Using your torque wrench, tighten the clamp bolt to the exact torque specification provided in your repair manual. This is critical for achieving the correct belt tension.

- Double-Check the Alignment: After tightening, double-check the alignment of the timing belt with the pulleys. Make sure the timing marks align correctly.

- Rotate the Engine Manually: Rotate the engine manually (by hand, using a wrench on the crankshaft pulley) at least two full rotations to ensure the timing is correct and the belt runs smoothly. Listen for any unusual noises or signs of interference.

- Final Tensioner Tightening: If your tensioner requires it, tighten the tensioner bolt or nut to its final torque specification.

- Reassemble Components: Reinstall all the components you removed in reverse order. This includes the engine accessories, splash shields, wheels, and any other parts.

- Reconnect the Battery: Reconnect the negative battery cable.

- Start the Engine and Verify Operation: Start the engine and listen for any unusual noises. Allow the engine to run for a few minutes, checking for leaks and ensuring everything is functioning correctly.

Common Mistakes to Avoid

Avoiding common mistakes can prevent costly repairs and ensure the longevity of your engine. Here are some pitfalls to steer clear of:

- Using the Wrong Torque Specifications: Always use the correct torque specifications provided in your vehicle’s repair manual.

- Over-Tightening or Under-Tightening: Both over-tightening and under-tightening can damage the timing belt and related components.

- Not Replacing the Tensioner: The tensioner is a critical component, and it’s often recommended that it be replaced when replacing the timing belt.

- Misalignment of Timing Marks: Ensure the timing marks are aligned correctly before tightening.

- Not Rotating the Engine Manually: Always rotate the engine manually after tightening the belt to verify proper operation.

- Forgetting to Disconnect the Battery: This is a crucial safety step to prevent electrical hazards.

When to Seek Professional Help

While many DIY enthusiasts tackle timing belt replacements, there are times when seeking professional help is advisable. If you lack the necessary tools, experience, or confidence, it’s best to consult a qualified mechanic. If you encounter difficulties during the process, don’t hesitate to stop and seek expert assistance. A poorly installed timing belt can lead to significant engine damage, making it a costly repair. Your mechanic will have the expertise and specialized tools to ensure the job is done correctly.

The Importance of Regular Maintenance and Inspection

The timing belt is a wear-and-tear component. Adhering to your vehicle manufacturer’s recommended maintenance schedule is crucial. Regular inspections can help identify potential issues before they lead to failure. Pay attention to any unusual noises, such as squealing or ticking, which could indicate a problem with the timing belt or related components. Look for signs of wear, such as cracks, fraying, or glazing on the belt. If you suspect a problem, have your vehicle inspected by a qualified mechanic promptly. This proactive approach can save you from potentially costly engine repairs down the line. Proper timing belt clamp tightening is just one aspect of this preventative maintenance.

Conclusion: Precision and Care for Engine Longevity

Mastering timing belt clamp tightening is a skill that requires precision, attention to detail, and a thorough understanding of your vehicle’s engine. By following the step-by-step guide and adhering to the best practices outlined in this article, you can confidently replace your timing belt and ensure the continued smooth operation of your vehicle. Remember to prioritize safety, use the correct tools, and always consult your vehicle’s repair manual. Regular maintenance, including timely timing belt replacement and proper timing belt clamp tightening, is essential for maximizing engine life and avoiding expensive repairs. Taking the time to do it right, including the crucial steps involving the timing belt clamp, is a worthwhile investment in your vehicle’s long-term performance and reliability. [See also: Related Article Titles]